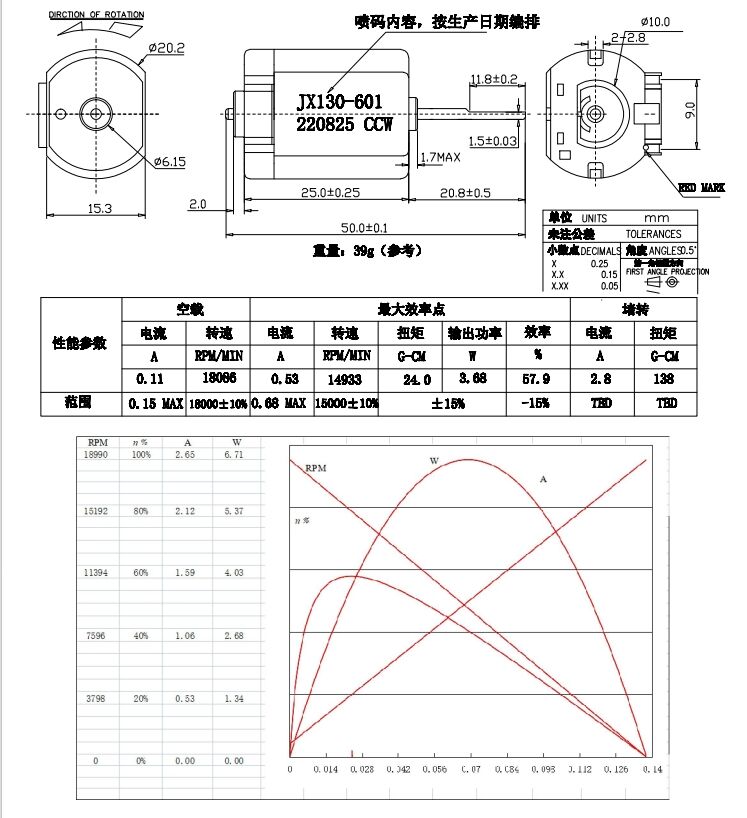

Features of this product

CW

Plastic end cap

Ferrite magnet

Carbon brush

Carbon steel shaft

Please contact us to serve you!">

Please contact us to serve you!">

The motors integrated into automotive rear-view mirrors serve a critical

role in facilitating precise adjustments of mirror positions. These motors are meticulously designed to be compact and fit snugly within the limited space available in the mirror housing. They enable electronic control of mirror angles, empowering drivers to conveniently adjust their rear-view mirrors from inside the vehicle with the push of a button. This technology significantly enhances driver visibility and safety by allowing quick and accurate mirror adjustments without the need for manual manipulation. The motors used in rear-view mirrors are engineered for exceptional durability and reliable performance, ensuring consistent operation over the lifespan of the vehicle. Their integration represents a fundamental component of modern automotive systems, optimizing driver comfort, convenience, and safety on the road.

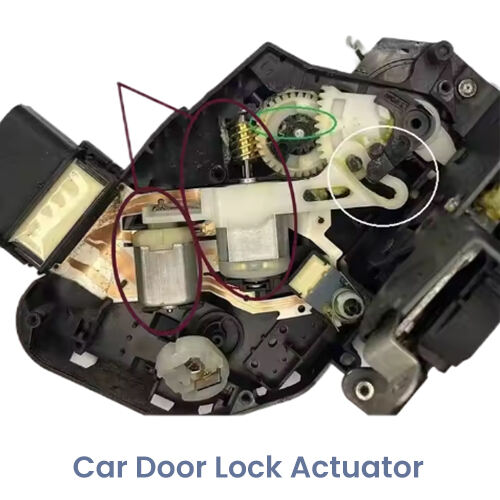

Application

Production Process

1.Design Phase:

•Determine the performance requirements of the micro motor, including power, speed, voltage, and other parameters.

•Design the structure and dimensions of the micro motor, selecting suitable materials.

•Utilize CAD software to create a three-dimensional model of the micro motor and conduct simulation analysis.

2.Parts Procurement:

•Procure various components according to the design requirements, such as wires, magnets, coils, bearings, etc.

3.Manufacturing Process:

•Process the purchased materials through milling, turning, drilling, and other techniques to produce various components of the micro motor.

•Wind the coils to ensure the number of turns and wire diameter meet the design requirements. Magnetize the magnets to ensure the magnetic field strength meets the design specifications.

4.Assembly:

•Assemble the processed components into a complete micro motor structure.

•Pay attention to the accuracy of installation positions and directions, ensuring proper coordination between components.

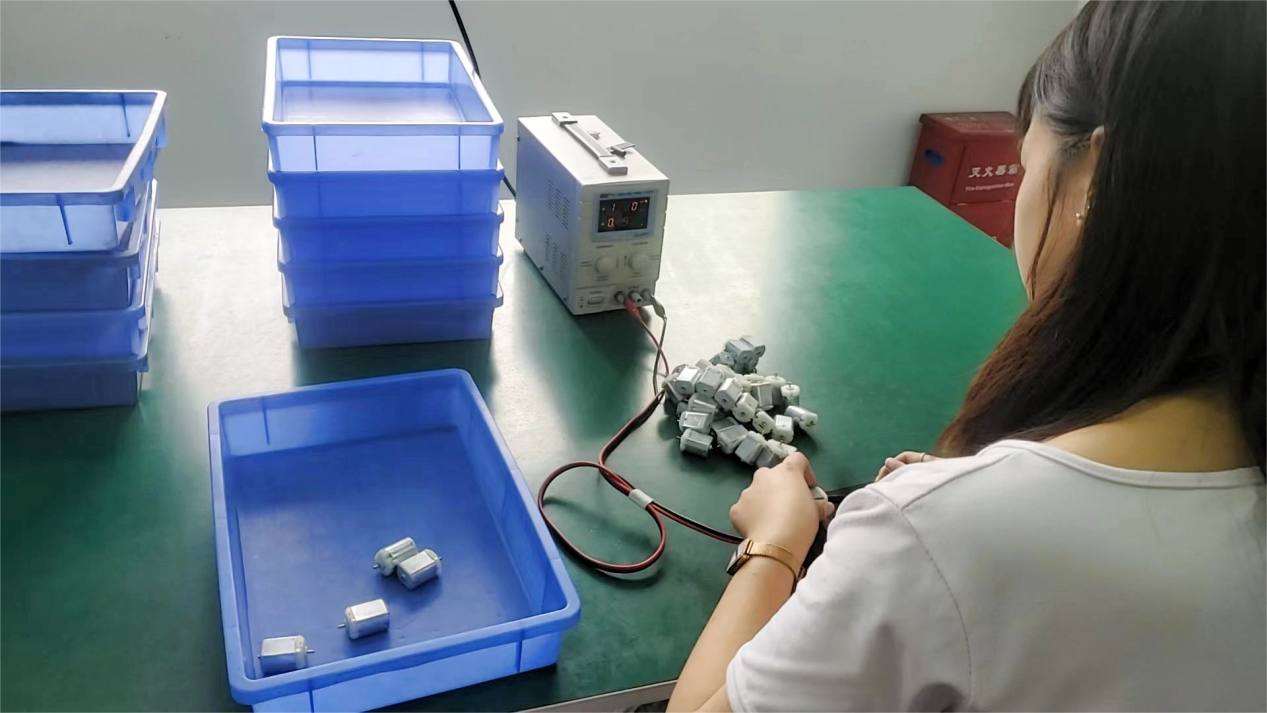

5.Testing and Debugging:

•Conduct preliminary testing of the micro motor by powering it on and checking the operation of each component.

•Test the performance indicators of the micro motor, such as speed, power, efficiency, etc. Identify and rectify any potential issues.

6.Quality Control:

•Perform quality inspections on the manufactured micro motors to ensure compliance with relevant standards and regulations.

•Conduct lifespan testing and environmental adaptability testing if necessary to validate the reliability and stability of the micro motors.

7.Packaging and Shipping:

•Package the micro motors that have passed quality inspections using appropriate packaging materials and methods to prevent damage during transportation.

•Prepare shipping lists and relevant documents, arrange logistics transportation, and deliver the micro motors to customers.

1.What are the primary applications of your micro-motor products?

Our micro-motor products find applications in various fields including automotive, robotics, consumer electronics, and medical devices.

2.What types of micro-motors does your company offer?

We offer a range of micro-motors including brushed DC motors, Geared motors, and customized solutions tailored to specific customer requirements.

3.Do you provide technical support for integrating your micro-motors into our products?

Yes, we offer comprehensive technical support to assist customers with the integration of our micro-motors into their products, including design consultation and troubleshooting assistance.

4.What quality assurance measures are in place for your micro-motors?

We adhere to strict quality control standards throughout the manufacturing process to ensure that our micro-motors meet the highest quality and reliability standards.

5.What is the typical lifespan of your micro-motors?

The lifespan of our micro-motors depends on various factors such as operating conditions and maintenance practices, but they are designed to provide long-term reliable performance.

6.What is the typical production lead time for your products?

Our production lead time varies depending on the quantity ordered by the buyer, usually ranging from 25 to 45 days. Material procurement takes 10 to 15 days, and scheduling takes one to two weeks.

7.What are your company's payment methods?

Our payment method is T/T (Telegraphic Transfer), with 30% required as a deposit, and the remaining balance to be paid before shipment.You can make payments either through Alibaba's payment platform or directly to our bank account.

8.Can you print my serial number on the motor?

Yes, we can imprint your serial number or company name on the motor according to your request.

9.What sets your company apart from other micro-motor manufacturers?

Our micro-motors are known for their exceptional stability in quality, and we maintain strict control over our production lines. One of our flagship models is the F280, which is specifically designed for automotive door locks. We have developed hundreds of variations of door lock motors for automobiles. Our expertise in automotive accessory motors spans many years.

10.Do you offer volume discounts for bulk orders of your micro-motors?

Yes, we offer competitive pricing and volume discounts for bulk orders of our micro-motors, allowing our customers to benefit from cost savings for large-scale projects.

11.How can I request a quotation for your micro-motors?

You can request a quotation for our micro-motors by contacting our sales team directly through our website or by sending an email to [email protected]. Please provide details about your requirements, and we will be happy to provide you with a personalized quotation.

2024 © Shenzhen Jixin Micro Motor Co.,Ltd - Privacy policy